By Sam Winnegrad

In the ever-evolving landscape of eyecare, the incorporation of prism thinning in prescription eyewear has become increasingly common. However, some eyecare professionals, not fully acquainted with the concept of prism thinning, may unwittingly reject properly crafted glasses, suspecting an error in lens production. Reading base-down prism in progressive lenses is now routine, thanks to prism thinning and advancements in PAL algorithmic technology. Unfortunately, if eyecare professionals lack a comprehensive understanding of this phenomenon and the reasons behind employing prism thinning, they might find themselves perplexed by the seemingly unconventional prescriptions. Moreover, this lack of awareness could lead to suboptimal patient care. A recent blind study involving a select group of individuals identifying as “opticians” revealed that only 61 percent comprehended the concept that a vertical prism yoked in the same direction cancels out the prismatic effect for the wearer. This underscores the imperative for continuous education within the eyecare industry to ensure professionals stay abreast of technological advancements and provide the highest standard of care for their patients.

Prism plays a pivotal role in eyecare with its ability to correct various visual anomalies. When integrated into eyewear, prism proves valuable in correcting misalignments and addressing issues like strabismus and other related disorders. One significant application of prism in ophthalmic lenses is the concept of “yoked” prism, which involves incorporating equal amounts of vertical prism into both lenses to rectify vertical imbalances and ensure binocular vision.

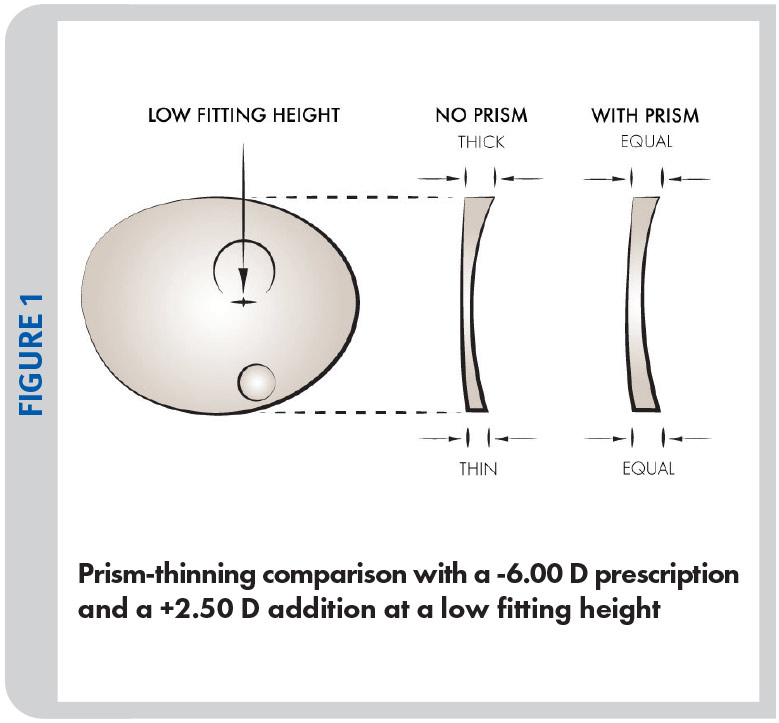

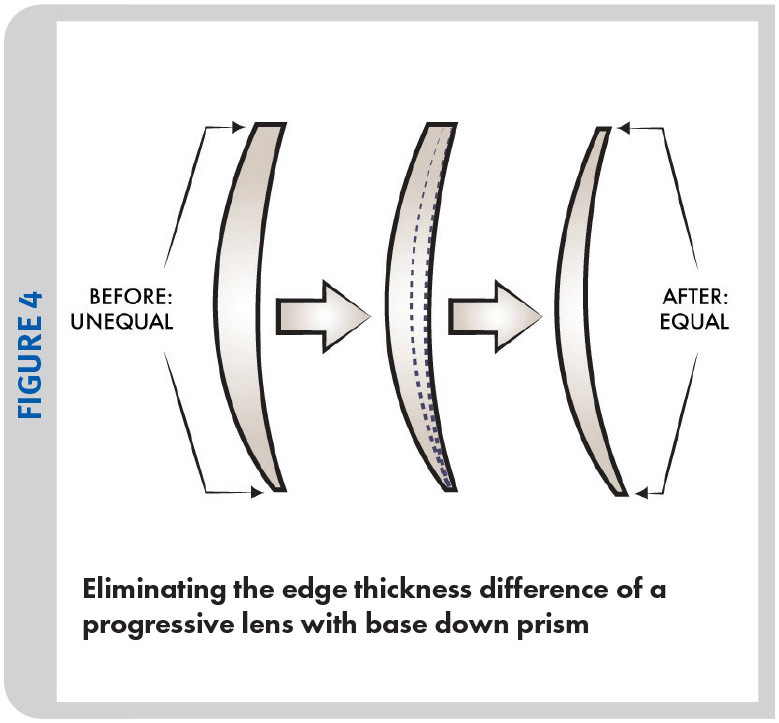

Expanding on the utility of prism in eyewear, prism-thinning emerges as a valuable technique in refining ophthalmic lenses. Prism-thinning, also known as equi-thinning, involves strategically grinding the prism into progressive lens blanks to reduce the thickness difference between the upper and lower edges of the lens. This technique is particularly beneficial for lenses with higher prescriptions or significant add powers, addressing challenges associated with progressive lens geometry. Prism-thinning not only maintains optical integrity but also enhances the aesthetics and comfort of eyewear, providing a visually pleasing and cosmetically appealing experience for the wearer. One other related benefit is the ability of prism-thinned lenses to reduce the difference in thickness between PAL lenses, which can differ greatly with some prescriptions.

Prism-thinned lenses address the inherent thickness differences between the upper and lower edges of the lens blank. This article delves into the background of progressive lenses, explores the challenges posed by their geometry and provides insights into prism-thinning techniques. By understanding and implementing prism-thinning correctly, eyecare professionals can enhance the cosmetics and comfort of progressive lenses.

Progressive addition lenses (PALs) introduce a unique curvature, gradually increasing toward the bottom to accommodate the desired add power. However, this design inherently results in a thicker upper edge compared to the lower edge, posing challenges for both aesthetics and wearer comfort. This thickness disparity becomes particularly conspicuous with plus-powered lenses, commonly prescribed for hyperopic individuals. Hyperopic lenses, known as farsighted or plus lenses, have a curved surface that converges light, bringing distant objects into focus. In the context of progressive lenses, the amplified curvature toward the bottom exacerbates the thickness difference, impacting the overall aesthetics of the eyewear.

The thicker upper edge of unmodified progressive lenses can be a source of aesthetic dissatisfaction for wearers. This thickness, especially noticeable in the upper half of the lens, may disrupt the sleek and minimalist design that individuals often associate with eyeglasses. Fashion-conscious wearers may find these thicker upper edges less appealing, and this can influence their decision-making when selecting eyewear. Additionally, the cosmetic challenge extends to the transition zone between the distance and near vision portions of the lens. The abrupt change in thickness may result in a visible line or distortion, further affecting the overall appearance of the eyeglasses.

Beyond aesthetics, the increased thickness in the upper portion of progressive lenses can impact wearer comfort. The additional weight and bulkiness may create discomfort during prolonged wear, affecting the overall satisfaction with the eyewear. Moreover, these cosmetic and comfort issues are not limited to plus-powered lenses but are also relevant to prescriptions with higher add-powers. For instance, wearers of multifocals designed for tasks like reading may encounter similar aesthetic and comfort challenges due to the increased curvature in the lower portion of the lens.

Prism-thinning emerges as a crucial solution to these challenges, addressing the thickness differences and enhancing both the visual appeal and comfort of progressive lenses. By reducing the overall thickness and weight through carefully calculated prism adjustments, opticians can offer wearers a more aesthetically pleasing and comfortable eyewear experience, meeting both functional and cosmetic expectations. As eyeglass wearers increasingly prioritize not only vision correction but also style and comfort, the implementation of prism-thinning becomes a valuable practice.

Consider the scenario of a normal flat-top bifocal, a classic design that has been a staple in eyewear for decades. This bifocal lens features a distinct line separating the distance and reading prescriptions, offering wearers a clear indication of where to look for different visual tasks. Now, envision a progressive lens with the same minimum edge thickness as this flat-top bifocal. On the surface, it might seem like a seamless transition between the two types of lenses. However, when you delve into the mechanics of progressive lenses, a complexity arises. The curvature of a progressive lens gradually increases toward the bottom to accommodate the add power required for near vision. This design, while addressing the multifocal needs of wearers, introduces a challenge—the upper edge becomes thicker than the lower edge.

This may sound rather wordy, but if you think about it, this thickness difference becomes more significant when we compare the progressive lens to its flat-top bifocal counterpart. The flat-top bifocal maintains a consistent thickness throughout its design, with no inherent need for increased center thickness. In contrast, the progressive lens necessitates more material at its center to ensure the same minimum edge thickness as the flat-top bifocal. This additional thickness in the center of the lens, required to balance the curvature, makes the progressive lens inherently thicker than its flat-top counterpart. It’s a nuanced optical intricacy that, while addressing the multifocal requirements, introduces a thickness disparity, impacting not only the lens aesthetics but also the wearer’s comfort. Understanding these nuances is pivotal for opticians as they strive to provide not just functional but aesthetically pleasing eyewear for their clients. The challenge lies in achieving a delicate balance between optical performance and cosmetic appeal, and this is where techniques such as prism-thinning come into play, offering solutions to enhance both the visual experience and the overall satisfaction of eyeglass wearers.

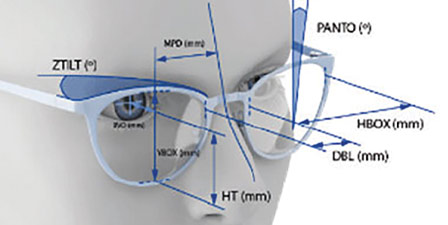

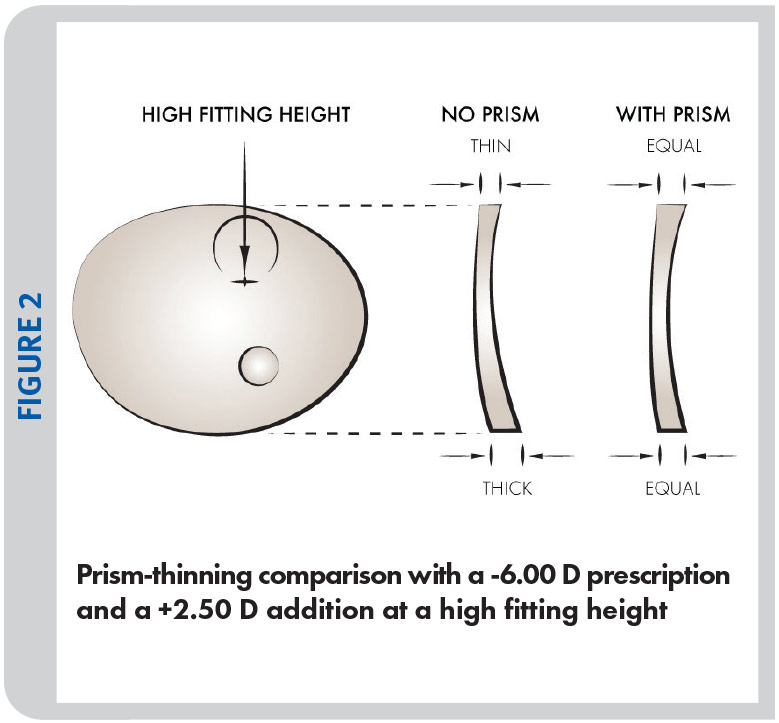

Fitting height, an essential parameter in eyewear customization, plays a significant role in the thickness dynamics of progressive lenses, especially when considering prism-thinning. This crucial dimension refers to the vertical distance from the bottom of the lens to the fitting cross—the point where the lens aligns with the wearer’s pupil. In the absence of prism, the optical center of a progressive addition lens (PAL) is typically ground at the prism reference point (PRP) of the lens, generally located at the geometric center of the lens blank, approximately 2 to 4 mm below the fitting cross.

As fitting height increases, especially in the case of high-powered lenses, the PRP—and consequently, the optical center—needs to be decentered upwards. This vertical decentering can result in a noticeable thickness difference between the upper and lower edges of the finished lens. The interplay between fitting height, lens power and decentering creates a complex dynamic that demands careful consideration during the frame and lens selection process.

The significance of fitting height becomes more apparent when we envision a pair of progressive lenses for a wearer requiring a substantial add-power. In such instances, the vertical decentering necessary to accommodate the high-powered prescription may contribute to a noticeable thickness differential between the upper and lower edges of the finished lens. The challenge intensifies with lenses featuring a steep add power, amplifying the thickness contrast.

Moreover, the influence of fitting height on lens thickness is not limited to progressive lenses alone. Executive-style multifocals, characterized by steeper segment curvature similar to that in PALs, face a comparable challenge. The inherent thickness difference between the upper and lower portions of the lens, accentuated by the steeper curvature, adds another layer of complexity.

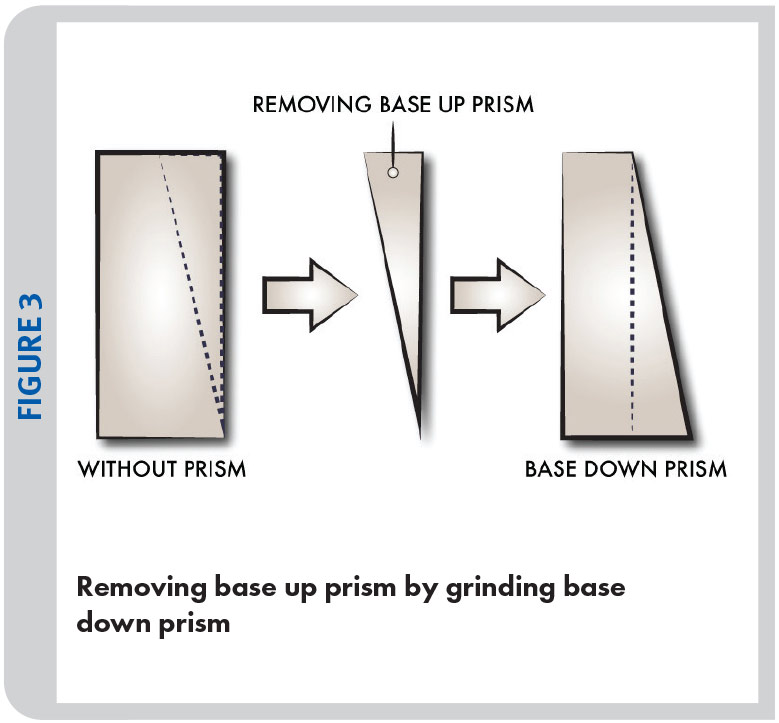

To counteract the inherent thickness challenges associated with progressive lenses, prism-thinning emerges as a sophisticated optical technique, offering both technical precision and enhanced aesthetics. Prism-thinning involves the meticulous process of grinding base-down prism into progressive lens blanks. This intricate method serves a dual purpose—balancing thickness differences and reducing the overall center thickness, thereby imparting a lighter feel to the lens.

The technical execution of prism-thinning is an integral aspect of its efficacy. Traditionally, during the generating process, the front surface of the lens is skillfully tilted on conventional generators, employing a prism ring to achieve the desired effect. Alternatively, the advent of three-axis generators has streamlined the process, eliminating the need for prism rings while still achieving the same outcome. This strategic tilting and grinding not only reduces unwanted thickness but also results in a substantial reduction in the overall center thickness.

The degree of prism-thinning applied is contingent on several critical factors, emphasizing the precision required in this optical adjustment. Parameters such as distance power (especially the power along the 90-degree meridian which will dictate the vertical thickness of the lens), add power, fitting cross height, fitting cross decentration and frame shape collectively contribute to the determination of the optimal prism-thinning amount. While a common rule-of-thumb formula suggests utilizing a base-down prism roughly equal to two-third of the add power, sophisticated laboratory software chock full of wonderous trade secret algorithms provides a more nuanced approach. This advanced software considers the interplay of all relevant factors, ensuring the calculation of the exact amount of prism-thinning required for the thinnest possible lens configuration.

Prism-thinning is not confined to plus-powered lenses; it extends its benefits to minus-powered lenses, presenting an effective solution to balance thickness differences. Depending on the fitting height, opticians may incorporate base-down or base-up prism to achieve a harmonious thickness distribution. While prism-thinning may not necessarily reduce the center thickness of higher-powered minus lenses, it excels in minimizing thickness differentials, contributing to a more aesthetically pleasing appearance.

Research findings suggest that wearers generally tolerate prism-thinning up to 2.00∆ without significant postural adjustments. However, exceeding 4.00∆ may lead to rejection by most wearers, necessitating careful consideration of these limits. Opticians must also be mindful of potential ghost images and deviations in reflected images that may become more noticeable in specific circumstances.

Accurate verification of lenses with prism-thinning is paramount, especially when replacing only one lens. Eyecare professionals can view a lens through their lensometer at the prism reference point (PRP) to ascertain the net vertical prismatic imbalance between lenses. This meticulous verification process prevents unwanted imbalances, ensuring a seamless visual experience for wearers.

In conclusion, prism-thinning stands as a valuable and intricate technique that elevates the cosmetics and comfort of progressive lenses. By addressing thickness differentials, eyecare professionals empower wearers with a visually appealing and comfortable eyewear experience. A thorough understanding of the factors influencing prism-thinning, precise determination of the right amount and meticulous verification procedures are indispensable steps in mastering this advanced optical adjustment. Eyecare professionals, in collaboration with processing laboratories, must stay abreast of advancements in lens technology to optimize prism-thinning, thereby delivering superior lens performance and the best care for your patients.

Sam Winnegrad, an expert in ophthalmic education and contact lenses, serves as the director of operations at University Eye Specialists in Knoxville, Tenn.