|

|

The Slab-Off Manufacturing Process

A slab-off lens is made using a procedure called bi-centric grinding. After the front surface of the lens is finished in the usual manner, a dummy, or cover lens manufactured to match the base curve of the required lens is then cemented onto the front surface. The front surface is then reground using the tool originally used for that surface, but ground in a way that the dummy is ground away in the upper portion while leaving it attached to the lower portion. The back surface is then finished with the remaining dummy considered as an integral part of the blank. The blank is now an equal thickness at the top and bottom unless the prescription calls for prism in the distance. When the lens is finished, the remaining dummy on the lower portion is removed. The dummy is base down prism resulting in the addition of base up prism in the lower portion of the lens. This procedure also results in an upward displacement of the center of curvature of the front surface of the lens in the lower portion, resulting in the front surface having two centers of curvature, one for the upper portion and for the lower, but both having the same curvature. This produces a unique optical axis for each of the two portions of the lens. Bi-centric grinding can be done on either the front surface in the case of a fused lens such as a glass flat top bifocal, or on the back surface in the case of a lens where the multi-focal segment results in a wedge on the front surface such as a plastic bifocal. |

In a situation where large amounts of vertical imbalance are present, for example, greater than 6D, consider using slab-off for one eye, and reverse slab for the other.

Digital lenses as slab-off: the ability of the lab to do digital cutting of the lens surface allows for a slab-off as part of the actual production of the lens when the prescription itself is being ground. Consult your lab for their ability.

Recommended Steps for Ordering

- Calculate how much vertical imbalance is induced by the distance lenses and determine if it will create visual discomfort for the patient

- Using Table 1, apply slab-off, or reverse slab to the appropriate lens

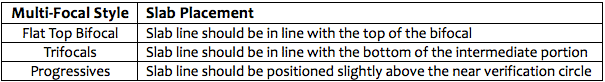

- Order the slab line placement at the appropriate position based on the multi-focal style being used as indicated in Figure 9

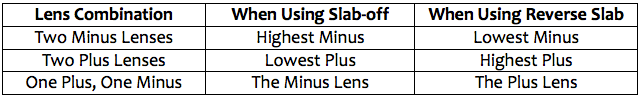

Lens Determination for Slab-off / Reverse Slab

The following table illustrates on which lens to place the slab-off / reverse slab depending on the lens combination being utilized. A simple way to remember the rule is to visualize the slab for what it is and what it provides to the optical system:

Slab-off provides base up prism so will always be applied to the lower part of the lens that is naturally inducing the most base down, or least base up prism when viewing through a position below the distance OC. Hence, the most minus, or least plus.

Conversely, reverse slab provides base down prism so will always be applied to the lower part of the lens that is naturally inducing the most base up, or least base down prism when viewing through a position below the distance OC. Therefore, the most plus, or least minus.

Table 1: Lens Selection for Slab-off/ Reverse Slab

|

It should be noted that although slab-off can be used on any lens, cosmetically it works best on a flat top bifocal due to the slab line forming a continuation of the top of the segment. In addition, the wider the bifocal used, the less noticeable the slab line will be.

Table 2: Placement of the Slab line

|

NOTE: When working with a progressive lens, your lab can often offer the best recommendation for the location of the slab placement depending on the progressive being used. Some patients wearing progressive lenses will often have a higher tolerance of vertical imbalance than with a lined multifocal due to a progressive's softer transition from distance to near. For this reason, it may not always be necessary to correct for moderate amounts of vertical imbalance.