By Preston Fassel

While the mass production of designer clothing in the 20th century made looking elegant an equal-opportunity affair, it also took something with it. In the days before Brooks Brothers let anyone with a Visa and a dream look like Don Draper, dressing well meant having a unique, concrete image in mind for yourself and a good tailor who could help bring the vision of the true you to life. No two outfits would be exactly the same, and any gathering of the well-dressed would be a cornucopia of subtly different styles, from a patch pocket here to a roped sleeve head there. True—mass production opened the doors for people from a variety of socio-economic backgrounds to look their very best, but those with a bit of extra pocket change or just dreams of sartorial excellency have always looked to custom tailoring as the most desirable alternative to truly embody one’s own personal style.

What if there was a middle ground, though? An opportunity for the mass produced to meet the custom tailored? A cost-effective, widely available solution that would allow the average consumer to fine tune his or her own aesthetic choices?

What if that solution came in the form of eyeglasses?

Toss those hypotheticals out the window. Thanks to Thema – A Family Factory, opticians can now offer a Milanese tailoring experience right in their very office—and the operation is based right here in the United States.

“We believe that more and more the consumer wants to establish a relationship with their frame,” says Giulia Valmassoi, whose father and uncles founded Thema in the Cadore Valley in Italy and who serves as the company’s North American director. “We give them the opportunity not just to select the shape, but to make it perfect… They used to go to an optical store and have to choose between frames that someone else has already designed for the customer. So they have to select from something that has already been designed, already produced and that already exists. Now, we believe that more and more often, the consumer wants something unique—something special. Something they feel they can truly own because they were part of the process of making and designing the frame.”

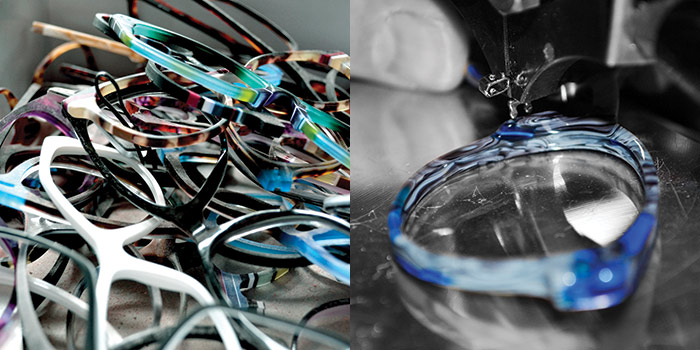

Thema’s i-Green line allows for unique customization of a pair of frames. Patients can select eye and bridge size, shape and color, as well as whether they would like nosepads, for a possible five million different combinations of acetate frames. (The company plans on launching a combination model.) For further customization, temples—made from an advanced form of TR-90 that offers even greater flexibility—are easily swapped out, allowing patients to purchase multiple pairs in a variety of colors. While Thema has offered the ability to customize for almost two years, their most recent push reflects a recent step the company has taken toward what Valmassoi sees as the future of eyewear: American manufacturing. To that end, the company recently opened a manufacturing plant in Miami—the first step the traditionally Italian brand has taken outside of its home country.

“We have combined Italian design ideas, research and development with U.S. manufacturing. That’s the top we can offer to our consumer, honestly,” Valmassoi says. “We actually brought our own specialists from Italy here to manufacture the frames. We had our masters from Italy that have 50 years of experience in the field here to teach this young team, young Americans, who are so fascinated by the Italian culture, and they are so proud of being able to learn from our masters and make their own frame in their own country. And this story leaves all of our customers extremely happy.” Not only does it make for an incredible story, but it dramatically reduces turnaround time: Over the past 18 months of i-Green’s custom program, it took an average of three weeks for an order to be processed in Italy and sent back to the U.S. And now? “Five business days,” says Valmassoi.

Aiding opticians in driving home the customization experience are a variety of P.O.P. tools made available to offices, from a mammoth freestanding display that acts as a sort of in-store kiosk and holds 100 interchangeable parts in multiple colors to a compact custom box that can be brought out and presented to the customer as a means of enhancing the boutique experience. More tech-savvy (or detail-oriented) patients also have the option to play with i-Green’s online configurator, which allows them to preview multiple permutations on their own time, then take their desired combinations back to the store for ordering. Valmassoi says it’s all part of a general move toward customization she sees taking place not just in optics, but across various strata of fashion.

“We have seen a change in consumers on how to approach customizable items. Up until five years ago, you never would have thought about customizing your shoes, your bags, any of your accessories. Now it’s becoming more and more common, even for the Millennial generation, to see Nike, Adidas or most luxury brands that until 10 years ago, you never would’ve thought about putting your initials on a Gucci bag or a Louis Vuitton brand, because that’s all people wanted. Now, it doesn’t matter. Branded, unbranded, they want to customize it. They want to be able to tell you that a particular color is something they chose; it’s not a standard color, it’s out of the ordinary.”

Most middle-Americans likely will never own a Saville Row suit or a handmade evening gown; however, thanks to i-Green, you can give your patients a unique experience: authentic, custom-made Italian eyewear. The sort Fellini would’ve worn, or Michael Caine or Sofia Loren. It’s not that three-piece suit from “Goldfinger,” but it certainly comes close. ■