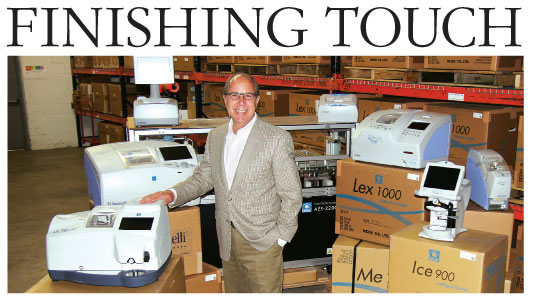

Gerard Santinelli started working at Santinelli International in high school, sweeping the floors and organizing the stock room at the lens finishing equipment distribution company founded in 1973 by his father, Joseph Santinelli. During college, he would attend trade shows with Joe, which whetted his appetite for the optical business and helped him cultivate his “finishing touch.”

After graduating from Boston University in 1981 with a B.A. in business management, Santinelli took a marketing job at Santinelli International. He was promoted to sales director and held the position for 10 years before being named vice president/general manager. Santinelli has served as president of Santinelli International since 1998 and chief executive officer since 2002.

Santinelli also served as a member of The Vision Council’s board of directors, as well as chairman of the lens processing technology division and the show committee. He has been an avid supporter of the Special Olympics Lions Club/International Opening Eyes Organization, and in 2004 was awarded the honor of “special friend” from the organization, which is dedicated to improving the vision care for persons with disabilities throughout the world.

—Andrew Karp

Karp: Santinelli’s tagline is “Perfecting the Art, Inside the Frame.” What exactly does it mean, and how does it describe Santinelli International’s approach to finishing lenses?

Santinelli: As lenses have become more complex in design, materials and coatings, and frame designs have become more creative with complex shapes, materials and Rx complexity, it has become our calling to assist the optical industry with the ultimate tools and advice needed to efficiently and effectively fabricate complex eyewear. Our tagline speaks to the precision, craftsmanship and beauty that our equipment delivers, empowering our clients to create ultimate eyewear.

This year, Santinelli International celebrates its 40th anniversary. Forty years ago, there was still some art in lens finishing, especially edging, which required some handwork. Today, the finishing process is almost entirely automated and depends on technology more than craftsmanship. How does art still figure into it?

Though craftsmanship is now built-in with our highly advanced technology, the final product is still a work of art. But the art doesn’t stop there. Our technology enables our clients to buy frames and lenses differently. Many have shared with us that their entire mindset of looking at frame vendors and buying and stocking their frame shelves and offerings has drastically changed. They’ve become more ambitious, creative and freer to offer their patients eyewear they had not previously considered because of the ease, simplicity and confidence our finishing equipment has provided for them.

Your family traces its roots in the lens finishing business back three generations to your great- uncle, Arthur Lemay. He invented the first modern automatic edger which could cut lenses in curved shapes for fashion eyewear. Your father, Joe Santinelli, learned the business from him. What are some things about the business that you learned from Joe?

His passion for the industry was instilled in me at a very young age. My father taught me first and foremost, the importance of the client. Our entire organization is governed by the principals of “customer first.”

Being the best that you can be was another major value. It’s also important to listen when you have your name on the building, the letterhead, the equipment; your reputation is on the line. You must deliver trusted advice and stand behind your products and what you say.

Last, but definitely not least, is service. It’s what we’re all about at Santinelli: ease, accessibility and professionalism. For me, taking over my father’s legacy, quality in everything we do is paramount. I’ve got big shoes to fill.

How would you describe your management style, and how is it different than your father’s?

I would describe my management style as progressive, engaging, customer- and employee-centric and personable. I tend to be more analytical and detailed than my father. But we’re both very creative and love the technological innovations side of our business. My father is a much better joke teller than I am, though. That’s a trait I wish I had inherited more of.

Santinelli International has continued toevolve along with the industry and is responsible for bringing some important technological advances to the market. What are some of your company’s most important innovations, in your opinion?

From our earlier years, with the advent our famous PatternMaker from FOMAP/Italy, we brought to market the concept of making a pattern, or tracing and making a pattern of every frame, to fabricate the perfect fit, first time, every time. Then there was the Crystal Cut Polish Edge, which we introduced and perfected and is to this date, the ultimate finish. We also introduced 3-D Tracing, which today we’ve taken to a higher level with the introduction of our new, automated high-curve tracers. Then there’s our 3-D Drilling and Grooving which our clients have grown to rely on. But there have been so many other automated technologies and software… and there’s so much more to come. Stay tuned.

Santinelli International and Nidek have had a close partnership for two decades. What sustains this partnership? What does each company contribute to make it work?

This is a special partnership I’m really proud of. We work hand-in-hand with Nidek to develop the most advanced, easy-to-use technology. We provide them with feedback from our clients, as well as suggestions for improvements or new ideas, such as the Click Mode software to make Chemistrie sun lenses—an industry first. They are brilliant engineers and businesspeople, and are extremely receptive and respectful of our input. As a major partner with Nidek Japan, I have served as chairman for Nidek’s worldwide lens edger summit meeting, raising our recognition and contributions internationally.

What skills are needed to succeed in the lens finishing business today, compared to 20 years ago?

Adaptability is important, as frames and lenses are constantly evolving. A desire to learn, improve and provide top-notch service are needed as well. Being business-savvy and a smart lens buyer is also huge. These skills will allow the ECP to keep all their jobs in-house, including the drill and high curve jobs, which leads to greater client satisfaction and increased profitability.

What advice would you give a young person looking to break into the business?

Learn from the bottom up, which is probably true for any business. Work retail so you get the direct contact with the patient and learn the importance of good service.

Spend some time working in a wholesale lab to learn how the high production side of the business works. From there you’ll see if you gravitate toward either one of those work environments, or if you want to go toward the vendor side.

Always take the job that will be most enjoyable. If it pays the most, you’re lucky. If it doesn’t, take it anyway. The goal of life is to be a happy person, and the right job is essential to that.

Lastly, network intensely and never take shortcuts. That can be construed as sloppy, a real career killer.

Is the next generation of Santinellis going to continue in the family business?

There are many possibilities, since we have a large family involvement in the company now. Collectively we have lots of high school and college-age kids who have grown up going to Vision Expos, hearing our business conversations at home and seeing our company featured in magazine articles and advertisements. I have my eye on one or two particular potential protégés that I think would be great leaders of the company one day. I hesitate to publish their names though, for fear our competition would try to recruit them! ■